1. To meet the requirements from BS5250 how much roof ventilation do I need?

Understanding how much ventilation is required within a roofspace is not always straightforward. However, here are a few useful tips and guidelines to get you started which will work in almost all common roofs;

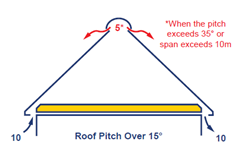

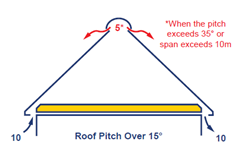

For roof pitches of more than 15º

10,000mm²/m is needed at the eaves. Pitches above 35° or with a span exceeding 10m, allow an additional 5,000mm²/m at the ridge.

For flat roofs and pitches of 15° or less

25,000mm²/m is required at the eaves or low level to ensure a cross flow of ventilation.

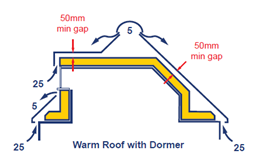

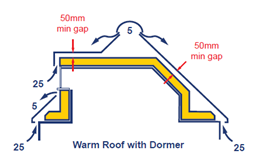

For warm roof details

25,000mm²/m is required at the eaves, with 5,000mm²/m at high level and a continuous 50mm gap between the insulation and membrane. Dormer windows, fire barriers and pitch changes etc., create separate voids within the roof space, ventilation must be maintained to these areas at high and low level.

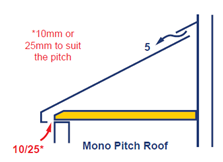

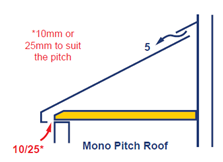

Mono pitch roof details

5,000mm²/m ventilation gap at high level, with 10,000mm²/m or 25,000mm²/m at low level depending on the roof pitch.

(For further information on the ventilation requirements for the control of condensation in buildings, refer to BS 5250)

2. How many Felt Lap Vents are required for my loft space and how far part should they be spaced?

Our Felt Lap Vent (G630) is a popular product for helping increase ventilation retrospectively within loft spaces that are suffering with condensation problems.

To get you started, we would recommend placing one ventilator into every other rafter bay down at low level. This should then be repeated on the opposing side. The vents will help to combat the problem of condensation build up in any roof space with a lapped felt / membrane construction. Please be aware that the opening of felt laps on the property may adversely increase the wind uplift load on the tiles/slates and affect the driving rain resistance of the roofing felt, for more information see BS 5534:2003, 5.8.1 & 6.2.1.1.

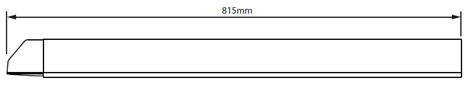

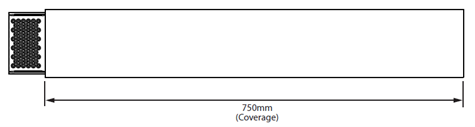

3. What is the free airflow value of the G504 1.25m Roll Panel?

The product provides an unobstructed, continuous gap of 25mm, which equates to 25,000mm²/M.

4. Can the G504 be trimmed to suit a shorter eaves length?

Yes, the product can be easily trimmed to suit the eaves detail using suitable cutting tools on site.

5. Do the G504 panels need to be unclipped at the popper connectors?

No, the popper connectors are a crucial design feature, allowing Manthorpe to create the unique extended width of 1.25m.

6. Can the G504 panels be overlapped to further increase the panel width?

Yes, if you have a detail that requires, the roll panel can be overlapped either with a second G504, or with another product within our roll panel range.

7. How is the G504 roll panel fixed to the rafters?

The roll panel can be simply stapled or nailed to the top face of the rafters. The roofing underlay and battens should then be installed as soon as possible to prevent strong wind and sun light damage to the roll panel vent.

8. Can the roll panel be used for a hipped roof detail?

Yes, the roll panel is also suitable for a hipped roof detail. Please see link below for step-by-step fitting instructions explaining how this can be easily achieved.

MBP1143d - G500, G502, G503 & G504 Roll Panel Vent Fitting Instructions (web).pdf (manthorpebp.co.uk)

9. How many G504 Roll Panel vents are in a box?

The 6m G504 roll panel comes in boxes of 2

10. Can the G504 roll panel be used for a hipped roof detail?

Due to the versatile, castellated profile design, the roll panel can be rolled out and secured in place without the worry of uneven rafter centres.

If you need more information or advice on roof and eaves ventilation or any other aspect of a specific project, you can get in touch with us through our contact page webform or by email or phone, and we’ll be happy to help.